OSTP chose Microsoft Sustainability Manager

Several years ago, OSTP embarked on an ambitious journey to redefine itself as the most efficient and sustainable company within its industry, aiming to achieve carbon neutrality at its sites by 2025. To achieve this the company knew that using and analyzing data is an important factor. “Measuring your performance is what allows you to improve,” says Andrea Gatti, CEO at OSTP Group. ”With this in mind the company set up a sustainability road map for how to work towards its goal."

Since the introduction of their sustainability road map, OSTP have seen a reduction in direct CO2 emissions from their production sites by roughly 70% between 2021 and 2023. The ability to track and record data is crucial to continue the course to achieve their goals.

In this case, you will discover how OSTP pioneered the Microsoft Sustainability Manager to make their journey toward CO2 emissions neutrality at their own sites and compliance with the new European Corporate Sustainability Reporting Directive (CSRD) easier and more efficient. The story is a summary of the original customer case published at microsoft.com.

CHALLENGES

OSTP specializes in producing welded stainless-steel tubes, pipes, fittings, and essential components across industries such as water treatment, construction, shipbuilding, and energy solutions. Recently, their tubular products have found application in EV battery giga factories.

Despite the 100% recyclability of OSTP's stainless steel products, the steel production process remains a significant contributor to global CO2 emissions. OSTP wants to minimize its environmental impact and have set a lofty goal. “We want to be CO2 neutral at our own sites by 2025,” says Andrea Gatti. “For us, the priority is minimizing our base footprint, and to do that, we need to measure emissions very carefully—and very accurately.” Enabling easier collection and reporting of sustainability data is crucial in the continued journey. To gain deeper insights and being able to increase the amount and quality of data-based decisions and improvements is a cornerstone in achieving the goals more efficiently.

We want to be CO2 neutral at our own sites by 2025.

OSTP also prioritizes compliance with the European Corporate Sustainability Reporting Directive (CSRD). The CSRD is a mandate from the European Union requiring companies to report sustainability information in three categories: Scope 1 (direct emissions), Scope 2 (indirect emissions), and Scope 3 (upstream and downstream activities such as transportation, operational waste, and purchased goods and services). To simplify CSRD compliance for all, OSTP wants to provide its employees and customers with automated, accurate reporting on emissions data.

With these ambitious targets in view, the company needed to build a cloud-based system that could aggregate information and deliver insights quickly. “We’ve started to measure emissions and make the data transparent to our customers,” Gatti says. “That forward movement gives us a competitive edge.”

APPROACH

In partnership with OSTP, we developed a digital platform that includes the Sustainability Manager, Azure Data Platform, and various Microsoft tools. This platform collects and presents information about CO2 emissions. Using the Sustainability Manager, OSTP can bring together all its data in one place, giving a clear picture of how their actions impact the environment across the company's operations and supply chain. They can track emissions in real-time and use this information to take specific steps to lessen their impact.

“We want to be transparent throughout the whole chain so customers can see and make the right choices based on the facts,” says Jyrki Sironen, Sustainability Manager at OSTP.

Watch the persons paving the way for data-driven sustainability tell more about the project in this video.

RESULTS

OSTP has done a proof of concept using Microsoft Cloud for Sustainability to digitize sustainability reporting, optimizing the use of emissions data across the company and providing transparency to customers.

“We’re using data to identify other areas beyond CO2 where we can reduce our environmental footprint,” says Anders Brännbacka, Operations Development Manager, Jakobstad and Digitalization Coordinator at OSTP Group. “We’re also targeting operational efficiency and see that as a synergy to drive our sustainability measures.”

Looking ahead, OSTP can use this continuous flow of information to find more ways to improve and be more efficient. The real-time emissions data is helpful for customers, too. When customers purchase from OSTP, they need to report on scope 3 emissions, and having accurate CO2 data from OSTP saves them time and effort.

Measuring your current performance is what allows you to improve. That’s why tools like Microsoft Cloud for Sustainability and Sustainability Manager are so important.

Would you like to explore using Cloud for Sustainability too?

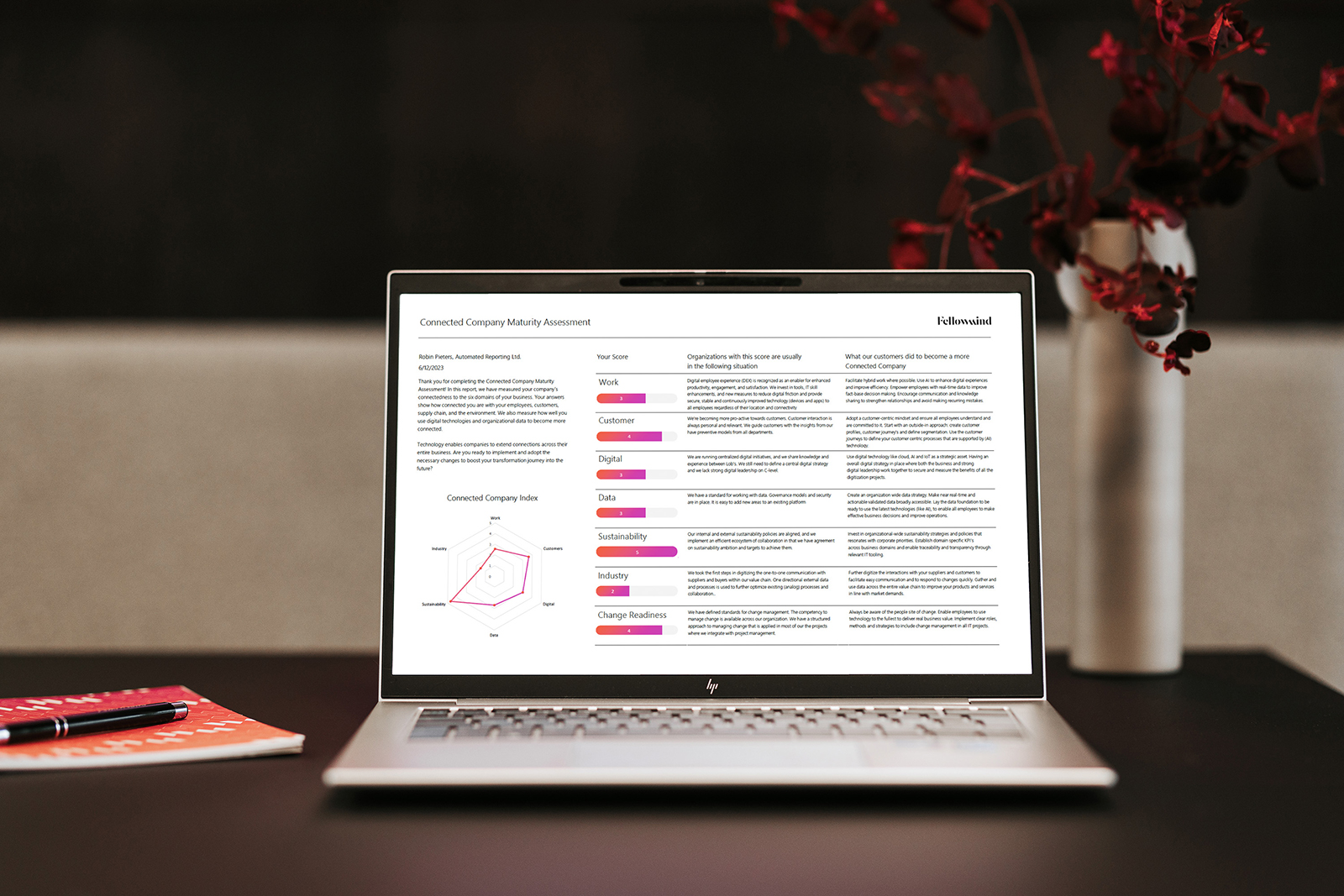

Are you ready to boost your transformation journey?

Let’s tear down silos, increase efficiency and exceed your customer expectations! We see how all domains of your business tie together and can help you become a Connected Company.

It all starts with an assessment to see how far you have come in your digital transformation journey and how ready your organization is for change. Take the next step and find out now!